Manufacturing Product Costing

May 9, 2019

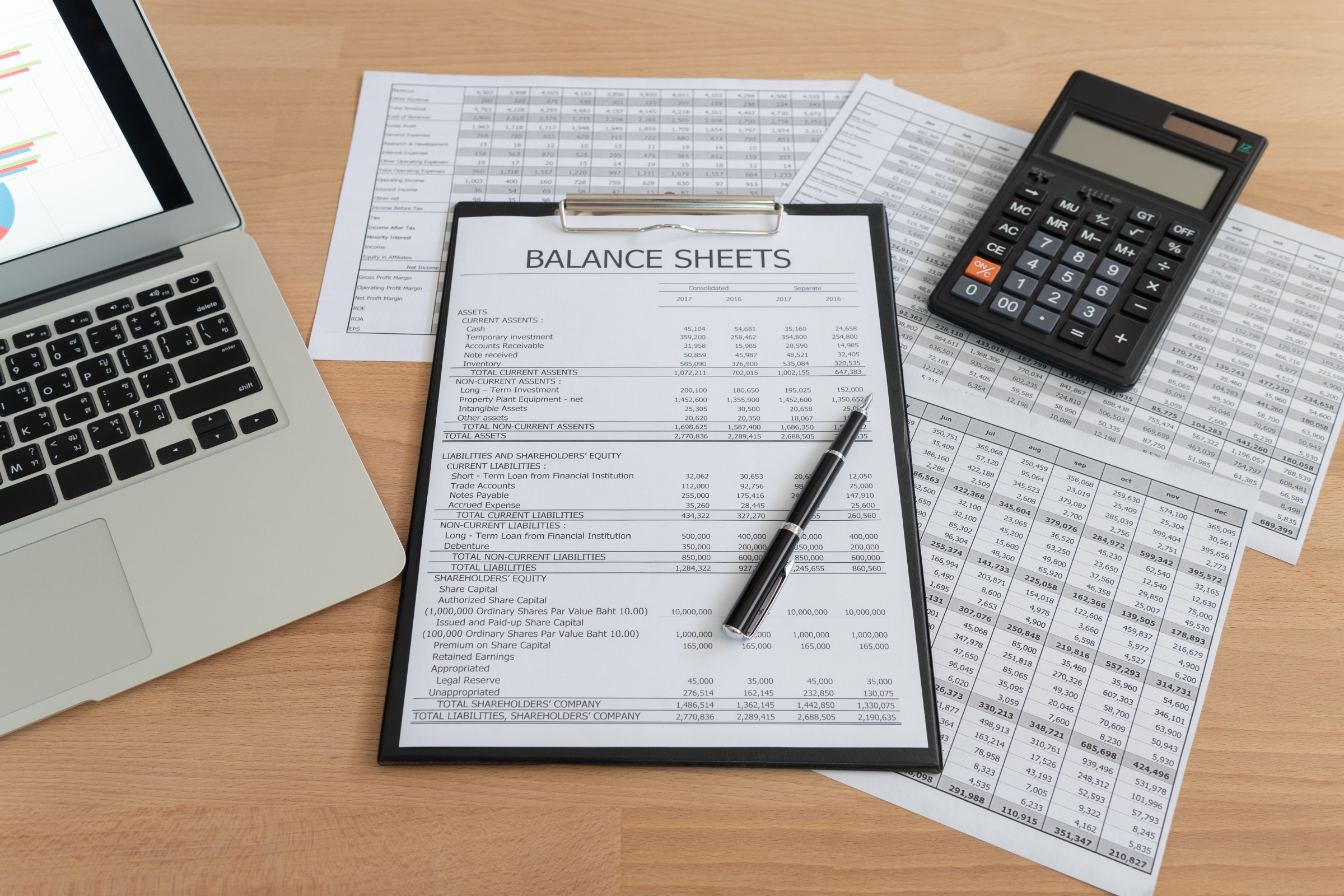

Manufacturers should have a firm grasp on how much it costs to produce their products. This knowledge ensures they can control expenses, account for future production needs, isolate inefficiencies, set appropriate prices on produced merchandise, and improve profit margins. Understanding production costs also allows a company to respond more effectively to changes in the market. But product costing is not as simple as adding up material costs and dividing by the number of produced units. There are many factors that a company must consider when determining overall product costs. Three of these are:

Direct materials

- This category includes raw materials that are part of the finished product and any cost of transporting the items to the facility.

Direct labor costs

- Direct labor costs are perhaps the easiest to recognize and apply. They include the gross salary-and-benefit costs for employees who directly contribute to manufacturing the product– including supervisors on the production floor.

Overhead

- Overhead includes all other costs that are neither direct materials nor direct labor. They can be indirect materials (such as shop supplies used in the manufacturing process), indirect labor (such as the salaries of factory maintenance workers), and factory-related costs. Most of these costs fall into two categories: fixed or variable.

A company may use several methods to allocate a company’s costs to each item. The two most common methods are job costing and process costing. Job costing is best when the production is for specific customers or jobs. In this case, the total cost of the job order is accumulated through the production process. Process costing is best when producing different products, and the costs can be allocated to those products by pre-established criteria. These include costing under the “units of production” method, whereby the firm divides the total manufacturing costs by the number of items that are produced.

A company must remain consistent in how it approaches product costing so that financial reports can be relied upon to capture the company’s current operating metrics. CRI’s manufacturing advisors understand the complexities of the manufacturing industry and are ready to help improve the accuracy and consistency of your monthly, quarterly, and annual reports. Contact CRI’s manufacturing team for help taking hold of your cost accounting and determining the best methods to implement efficient cost production.